compression test fiber plates|Compression Testing: Exploring Methods, Applications, and Benef : wholesale The “Boeing CAI” fixture is used to test the impact resistance of carbon and other fiber-reinforced polymer composite laminates. These materials are prone to great reduction in compressive . T1 EP.2 — Rinha de Picumãs. 5 de setembro de 2023. 1h 5min. 13+. Na disputa pela coroa, um cetro e um prêmio em dinheiro no valor de 150 mil reais, as queens precisam .

{plog:ftitle_list}

Seth Davenport is a man masquerading as a small-town Iowa preacher in hopes of starting a full-blown insurrection against the status quo. Focused on his mission, he is unaware .

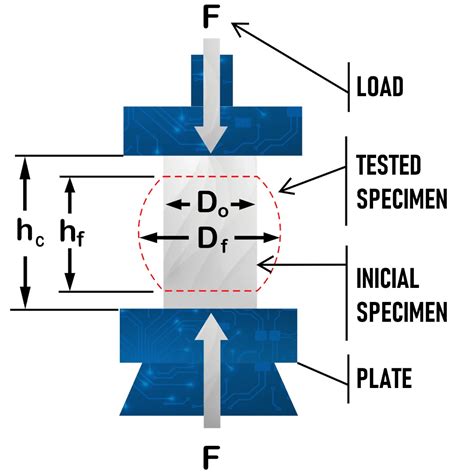

Compression platens are used to perform compression tests on a wide range of materials and components. When installed in a Universal Testing Machine they allow a variety of tests to be performed to determine compression modulus, .The “Boeing CAI” fixture is used to test the impact resistance of carbon and other fiber-reinforced polymer composite laminates. These materials are prone to great reduction in compressive .The specimen is typically placed under a compression plate or between two parallel plates, and a load is applied until the desired deformation or failure criteria are met. . Carbon Fiber Reinforced Polymer (CFRP): . How is a .Compression testing is one of the most fundamental types of mechanical testing, alongside tensile and flexion tests. Compression tests are used to determine a material’s behavior under applied crushing loads, and are typically conducted .

Compression Testing: Exploring Methods, Applications, and Benef

Compression Platens

Boeing and Airbus developed a special testing procedure to investigate the compressive response of laminates that have been impacted (following standards ASTM D 7137 and DIN 65561). This study focuses on both experimental and numerical analysis of Kevlar plates subjected to compression after impact. To ensure high quality and appropriate mechanical . In this work, compression tests after impact and numerical simulation are combined to study bearing capacity and failure mode of carbon fiber reinforced composite grid plates with reinforcing .

Composites Test Fixtures Compression After Impact, ASTM D 7137 / D 7137M www.instron.com Accessories for Materials Testing The “Boeing CAI” fixture is used to test the impact resistance of carbon and other fiber-reinforced polymer composite laminates. These materials are prone to great reduction in compressive strength, even when the

The parallel-plate compression test is one of the simplest ways to measure the mechanical properties of a material. In this test, the Young's modulus ( E) and the Poisson's ratio ( ν) of the material are determined directly without applying any additional modelling and parameter fitting in the post-processing.This is, however, limited when dealing soft biological .

Various mixture proportions, fiber types, and casting methods were considered. • Biaxial failure curves were constructed based on 127 plate specimen test results. • HPFRCCs can exhibit enhanced biaxial compression performance vs. plain concrete. • Modeling parameters were derived for nonlinear finite element analysis with HPFRCC. Background Several methods have been proposed to reduce plate construct stiffness and promote secondary bone healing. In this study, we explored the stiffness and strength of the new carbon fiber-reinforced poly-ether-ether-ketone (CF 50) plate compared with the titanium alloy plate (Ti6Al4V). Methods Titanium and CF-PEEK locking plates were tested .What is a compression test, its purpose and how it is performed. . Standard test method for compressive properties of rigid plastics and continuous fiber-reinforced composite materials (end loading compression) . Standard Test Method for Compressive Residual Strength Properties of Damaged Polymer Matrix Composite Plates; ASTM F1306 .

ASTM C364 provides guidance for in-plane or edgewise compression testing, and ASTM C365 covers out-of-plane or flatwise compression testing. Both compression methods help determine modulus data. To simulate in-service damage, composite sandwich panels undergo fatigue testing in either bend or compression to evaluate damage growth.

The plate load test on the soil–fiber stratum was performed to relatively high pressures, and gave a noticeable stiffer response than that carried out on the nonreinforced stratum. Test methods. The compression tests of the specimens with the loaded cross-section of 30 × 30 mm 2 were carried out on an Instron testing machine with an in-line 100-kN load cell under displacement controlled loading at a rate of 0.3 mm/min. The compression tests of the specimens with the loaded cross-section of 60 × 60 mm 2 and 90 × 90 mm 2 were . The load capacity of the test machine was up to 200 kN for both tension and compression test. In order to guarantee quasi-static loading, the loading rate was set to 1 mm/min. Referring to the test standard ASTM D7137 , a . resulting in a smaller maximum of the out-of-plane deformation and lighter fiber damage for the repaired plates, but . Axial compression performance tests were carried out on a 1:1 truss structure prototype, with a span of 18.5 m, using specific axial compression test equipment. The basic structural design, joint construction pattern, modular integration approach, unique connection method of rear connection-rings, and structural design of composite trusses were .

The damage mechanism of 2D woven fiberglass panels under random vibration loadings was investigated by means of an experimental analysis and compared with the damage mechanism under constant-amplitude loadings. Based on experimental observations, it was found that the failure mode under vibration loadings was delamination, and predicting the vibration . Axial Compression Test and Bearing Capacity Analysis of Biaxial Prestressed Angle Steel Plate Fully Wrapped Reinforced Concrete Short Column . because polymer fiber cloth is a type of anisotropic material, its strength and elastic modulus in the fiber direction are much greater than those in the perpendicular direction. . (RC3 > RC2 > RC0 . Fig. 1 illustrates a compression platen misalignment produced by a rotation along the fiber’s longitudinal × axis (angle θ) and a rotation along its horizontal transverse y axis (angle ϕ). In the case of a ϕ angle rotation, only part of the fiber will be compressed. The contact area is thus heavily affected. In contrast, the whole fiber length will still be compressed in the case of .

Composites Test Fixtures

Two configurations’ plates of Randomly Oriented (RO) and Highly Oriented (HO) were analyzed under quasi-static tension, compression, and shear loadings. To study the effect of fiber orientation, for HO plate, two fiber directions were chosen: HO-0° (parallel to the Mold Flow Direction (MFD)) and HO-90° (perpendicular to the MFD).

The parallel-plate compression test is one of the simplest ways to measure the mechanical properties of a material. In this test, the Young’s modulus ( E) and the Poisson’s ratio ( ν) of the material are determined directly without applying any additional modelling and parameter fitting in the post-processing.This is, however, limited when dealing soft biological .Composite patch repair using natural fiber for aerospace applications, sustainable composites for aerospace applications. Mohd Khirul Hafiz Muda, Faizal Mustapha, in Sustainable Composites for Aerospace Applications, 2018. 9.13 Compression test. Compression testing is one of the most important tests to determine the behavior of composite materials. . Mechanical properties of .

Fig. 1 shows the fabricated specimen whereby Fig. 2 illustrates the geometry of glass fiber laminated plates containing a central circular hole with . First, all the sixteen specimens (fiber-glass laminated plates) are prepared for running the compression test. The geometry of the specimen, the boundary conditions and the load conditions are .

Carbon fiber-reinforced polymer (CFRP) has the advantages of a high strength-weight ratio and excellent fatigue resistance and has been widely used in aerospace, automotive, civil infrastructure, and other fields. The properties of CFRP materials under high temperatures are a key design issue. This paper presents the quasi-static tensile mechanical properties of .A carbon fiber plate fabricated from standard modulus plain weave carbon fiber in a balanced and symmetric 0/90 layup has an elastic bending modulus of approx. 10 MSI. It has a volumetric density of about .050 lb/in3. . but not necessarily in compression or crush. In addition, the loading and boundary conditions for any components are unique . The purpose of this paper is to evaluate buckling strength of timber hybrid columns reinforced with steel plates or carbon fiber sheets. Buckling test is performed for the hybrid timber columns . This paper discusses the load–settlement response from three plate load tests (0.3 m × 0.3 m square, 25 mm thick) carried out on a thick homogeneous stratum of compacted cohesive soil .

Steel plates for welded steel bridge members typically supported on three or four edges. Average compressive stress–strain curves and ultimate strength are vital for assessing the stability of these plates. These metrics also form the foundation for developing beam-column models that account for local buckling. However, collecting this data presents significant . The slice compression test (SCT) is used to evaluate interfacial properties by loading/unloading a specimen of the composite between two plates; one has low modulus and the other has high modulus. The specimen used is an epoxy resin, containing a single SiO 2 glass fiber, with a 200 μm diameter. The interfacial debonding is monitored by using .

Ajude Mario a fugir das chamas lançadas pelo terrível Bowse.

compression test fiber plates|Compression Testing: Exploring Methods, Applications, and Benef